PerkinElmer의 'Determination of Arsenic and Selenium in Drinking Water by ICP-OES with Continuous Flow Hydride Generation using a Single Pre-Reduction Procedure'를 이용한 응용자료는 한국 퍼킨엘머에서 제공하였으며 주요 내용은 다음과 같다.

Introduction

The determination of arsenic(As) and selenium(Se) by ICPOES is challenging because both elements are weak emitters, which makes it difficult to measure low concentrations. In addition, in many sample types, both As and Se are present in low concentrations; the combination of low concentrations and inherently low signals makes it difficult to measure low levels of As and Se by ICP-OES.

One possibility to enhance the sensitivity of both As and Se is to convert them to their gas-phase hydride species by means of

the following reactions:

NaBH₄ + 3 H₂O + HCl → H₃BO₃ + NaCl + 8H [Eq. 1]

As3+ + H(excess) → AsH₃ + H₂(excess) [Eq. 2]

Se4+ + H(excess) → SeH₂ + H₂(excess) [Eq. 3]

By introducing the gases into the plasma and removing the aqueous components, more signal is generated, allowing lower

concentrations to be measured. This analysis is most effectively accomplished using a continuous flow system, in which samples

and a reductant are continuously pumped and mixed on-line.

Argon is then added to the mixture to carry the hydride gases to the plasma, while the aqueous component is removed and pumped to waste.

However, in order to form hydride species and obtain the best sensitivities, As and Se must be in their lower oxidation states: AsIII and SeIV. If As and Se are present in other oxidation states, they will either not form hydrides(Se) or will have lower sensitivity(As). This means that all samples and standards must undergo a pre-reduction step prior to analysis to ensure that any As and Se are reduced to AsIII and SeIV. Over the years, there have been many investigations into reducing As and Se to attain the strongest signals so that ever-lower concentrations can be measured.1-7 Unfortunately, the reduction chemistries of As and Se are different. This means that if a sample needs to be analyzed for low concentrations of As and Se by hydride generation, two different pre-reduction steps must be performed, and the sample must be run twice, which, in many cases, is impractical.

This work focuses on measuring As and Se in drinking water using PerkinElmer’s Avio 220 Max hybrid simultaneous ICP-OES

using a single pre-reduction procedure.

Experimental

Sample Preparation

To accurately assess the effectiveness of the pre-reduction procedures, AsV and SeVI standards(High Purity Standards, Charleston, South Carolina, USA) were used exclusively since these oxidation states do not form hydrides(SeVI) or will have lower sensitivity(AsV).

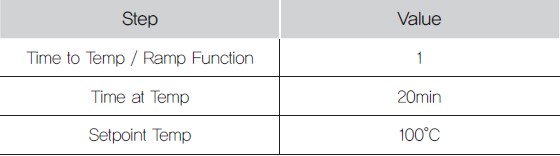

All samples, calibration standards, blanks, and spikes were prepared in 1%(v/v) nitric acid and then underwent the following Determination of Arsenic and Selenium in Drinking Water by ICP-OES with Continuous Flow Hydride Generation using a Single Pre-Reduction Procedure pre-reduction procedure. Equal amounts of concentrated hydrochloric acid(37%) and sample(or standard) were combined in 50mL DigiTUBEs(PerkinElmer, Shelton, Connecticut, USA), which were capped, shaken, and heated in an SPB sample preparation block(PerkinElmer) which followed the program in Table 1. After heating, the DigiTUBEs were removed and allowed to cool to room uploaderature before being diluted to their final volume with deionized(DI) water.

This procedure was evaluated at two different volumes: 10mL of sample + 10mL HCl diluted to a final volume of 25mL and 20mL sample + 20mL HCl diluted to 50mL; both volumes produced equivalent results. Each preparation procedure results in a 2.5x dilution of the sample.

All concentrations listed in this work are the nominal, predilution concentrations; the actual concentrations entering the plasma are 2.5x less.

It should be noted that the heating time in the sample preparation block will be dependent on the concentrations of As, Se and the mineral content of the waters: higher analyte concentrations and more complex matrices require longer heating times. The 20-minute heating time chosen here proved to be adequate for the concentrations and matrices evaluated in this work.

Table 1: Sample preparation block program for pre-reduction of arsenic and selenium.

The hydride-forming solution consisted of 0.5% NaBH4(w/v)+0.05% NaOH (w/v). Although the final samples were in 40% HCl(v/v), it was found that a wash solution of 15% HCl(v/v) was adequate.

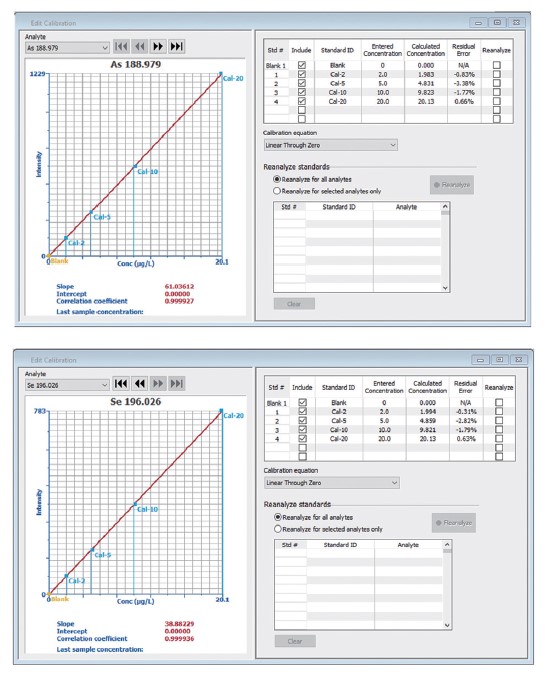

All quantitative measurements were made against linearthrough-zero external calibration curves from 2, 5, 10, and 20ppb standards prepared from AsV and SeVI stock standards, which were then carried through the same pre-reduction process as the samples.

To evaluate accuracy, the certified standard Trace Metals in Drinking Water-B (High Purity Standards) was used, along with spike recoveries in tap water samples collected locally. Spikes were made from the AsV and SeVI stock solutions and added prior to the pre-reduction process.

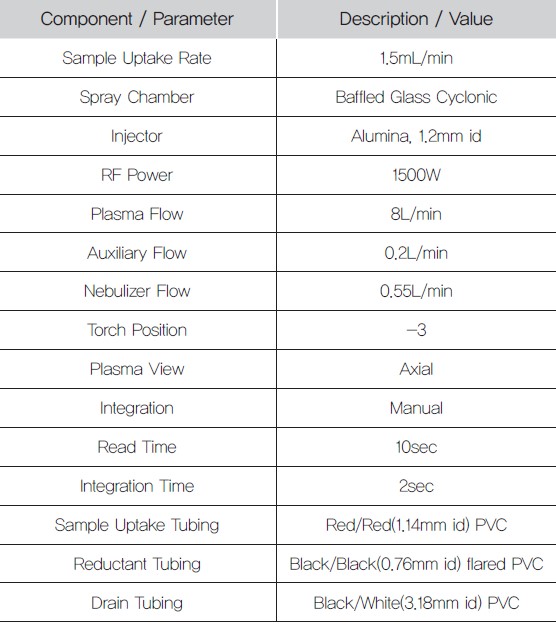

Instrumental Parameters

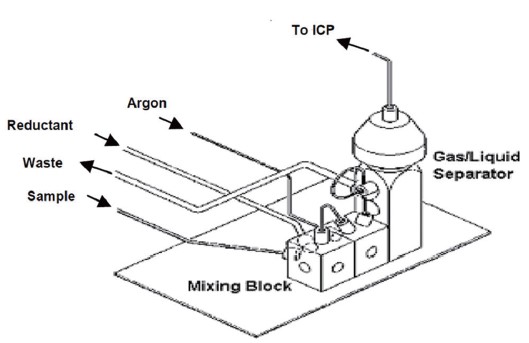

All analyses were done on an Avio 220 Max hybrid simultaneous ICP-OES using the conditions in Table 2, monitoring As 188.979 and Se 196.028nm lines. The sample was passed through a Chemifold mixing block(Figure 1) where it was mixed on-line with the NaBH₄/NaOH solution to form the hydrides. The hydride gases were separated from the liquid in the gas-liquid separator component of the Chemifold, with the gas passing through the spray chamber prior to entering the plasma. Although equivalent results can be obtained without the spray chamber, improved precision/lower RSDs were seen when the spray chamber was used.

The hydride gases entered the spray chamber through a 5cm piece of the Avio nebulizer gas line that was cut off and secured in the spray chamber in place of a nebulizer. The fitting that secures the nebulizer in the spray chamber also secured the tubing. Alternately, the universal spray chamber adapter(Part No. N0782031) could be used to couple the output of the Chemifold to the spray chamber.

To further improve precision, manual integration was used with an integration time of 2 seconds and a read time of 10 seconds. These parameters resulted in five readings per replicate, which improved the RSDs and allowed lower concentrations to be accurately measured. To simplify data analysis, automatic background correction(available in Syngistix™ for ICP software v. 5.1 or higher) was applied to all analyses.

Figure 1: Chemifold assembly for continuous flow hydride generation.

Table 2: Avio 220 Max ICP-OES instrumental parameters.

Results and Discussion

In this work, AsV and SeVI standards were used throughoutsince these oxidation states do not produce hydrides. This was done to evaluate the effectiveness of the pre-reduction procedure, which is vital when analyzing unknown samples where As and Se can exist in different oxidation states. Starting with AsV and SeVI represents the worst case scenario in a sample where all of the As and Se exist in oxidation states that do not produce hydrides.

An initial study was performed to assess the lowest concentrations that could be accurately calibrated, with the regression and the residual errors being used to evaluate the calibration curve. Equal concentrations of As and Se were used for the calibration standards. Typical calibration curves appear in Figure 2 and show that standards with a nominal concentration as low as 2ppb can be measured accurately, with regressions being greater than 0.9999. Because higher concentration standards can artificially improve the regression and make low concentrations appear to fall on the curve8, the residual errors of the calibration standards is a more effective means to evaluate the accuracy of the standards. For both the As and Se curves, the residual errors for all standards are less than 3.5%, signifying the accuracy of all the standards.

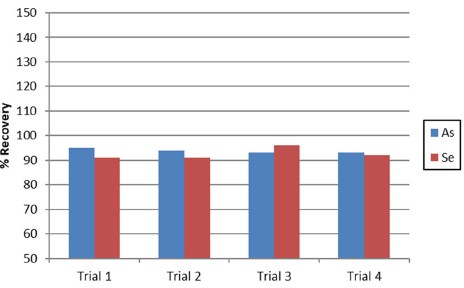

To evaluate the accuracy of the methodology, Trace Metals in Drinking Water-B(which contains 10ppb As and 11ppb Se) was measured. Figure 3 shows that the recoveries for both elements are within 10% of the certified values over four separate analyses, thereby validating the accuracy.

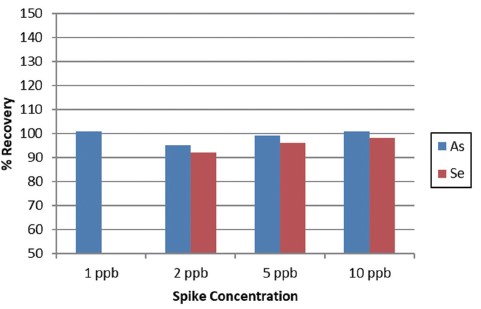

Several tap water samples were collected locally and analyzed. In all of them, neither As nor Se were detected. In order to determine the lowest concentrations that can be accurately measured with this methodology, a tap water sample was spiked with 1, 2, 5 and 10ppb AsV and SeVI and then analyzed, with typical recoveries shown in Figure 4. These results demonstrate that as low as 1ppb As and 2ppb Se can be accurately measured, well below global maximum limits for As(Generally around 10ppb) and Se(Generally 10-50ppb) in drinking water. Taking the sample preparation dilution factor into account, the Avio 220 Max ICP-OES performs accurate measurements on 0.4ppb As and 0.8ppb Se, unprecedented concentrations for accurate measurements by ICP-OES.

Figure 2: Calibration curves for arsenic and selenium.

If lower As and Se concentrations are required, other pre-reduction procedures have been published for both As2-4 and Se6,7, which can lead to enhanced sensitivity. The drawback is that these methodologies are specific for As or Se, meaning that the sample would have to be prepared two times with different procedures and analyzed twice to obtain results for both As and Se.

Figure 3: As and Se recoveries in Trace Metals in Drinking Water-B.

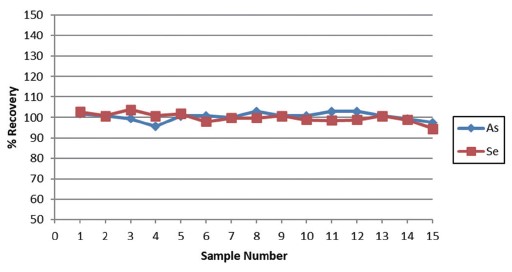

To assess the stability of methodology, a tap water was spiked with 10ppb AsV and SeVI and analyzed 15 times. With all recoveries for both elements within 10%(Figure 5), the stability of the system is established.

Figure 4: AsV and SeVI spike recoveries in tap water.

Figure 5: Recovery of a 10ppb AsV and SeVI spike in tap water over 15 consecutive measurements.

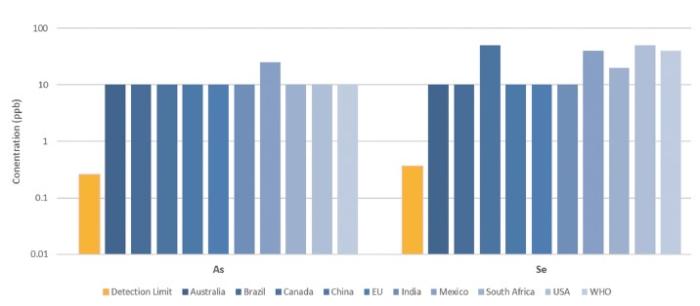

Finally, detection limits were evaluated by carrying a blank through the pre-reduction procedures and measuring it against the calibration curve, using the Detection Limits tool in Syngistix software and multiplying the standard deviation of 10 replicates by 3. The detection limits for As and Se are less than 0.5ppb, well below regulated maximum limits around the world, as shown in Figure 6.

Conclusion

This work demonstrates the ability to measure low concentrations of As and Se by continuous-flow hydride generation on the Avio 220 Max hybrid simultaneous ICP-OES using a single pre-reduction procedure for AsV and SeVI. Even though this pre-reduction procedure does not produce the optimum sensitivity for As or Se, when combined with the outstanding sensitivity of the Avio 220 Max, concentrations well below those which can be measured by ICP-OES with conventional sample introduction are achieved.

Figure 6: Arsenic and selenium detection limits(Orange), compared to regulated concentrations in drinking waters around the world(Shades of blue).

Reference(참고문헌):

1. “Continuous Flow Hydride Generation Using the Optima ICP”, Field Application Report, PerkinElmer, 2004.

2. Welz B., Sucmanov M., Analyst, 118, 1993, 1417-1423.

3. Chen H., Anal. Chem. 64, 1992, 667-672.

4. Yin X., Hofmann E., Ludke C., Fresenius J. Anal. Chem. 355, 1996, 324-326.

5. “Recommended Analytical Conditions and General Information for Flow Injection Mercury/Hydride Analyses Using the PerkinElmer FIAS 100/400”, Technical Note, PerkinElmer, 2004.

6. Wickstrom T., Lund W., Bye R., J. Anal. At. Spectrom. 6, 1991, 389-391.

7. Maleki N., Safavi A., Doroodmand M.M., Talanta, 66(4), 2005, 858-862.

8. “Sensitivity, Background, Noise, and Calibration in Atomic Spectroscopy: Effect on Accuracy and Detection Limits”, White Paper, PerkinElmer, 2017.

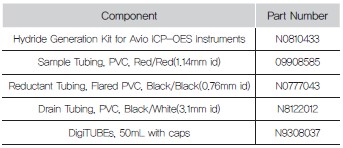

Consumables Used

PerkinElmer의 'Avio 220'에 관한 궁금한 내용은 본 원고자료를 제공한 한국 퍼킨엘머를 통하여 확인할 수 있다.

Model Name(모델명): Avio 220

The Person in Charge(담당자): Changhwan Lee

Maker(제조사): PerkinElmer

Country of Origin(원산지): Singapore

Mail inquiry: Chang-Hwan.Lee@perkinelmer.com

Data Services(자료제공): PerkinElmer Korea

<이 기사는 사이언스21 매거진 2021년 10월호에 게재 되었습니다.>