PerkinElmer의 'Characterization of Ultrapure Water Using NexION 5000 ICP-MS'를 이용한 응용자료는 한국퍼킨엘머에서 제공하였으며 주요 내용은 다음과 같다.

Introduction

For decades, the semiconductor industry has been continuously designing new devices that are smaller, faster and consume less power than their predecessors.

To maintain this trend, the critical features of these devices must become smaller and have fewer defects. The small diameter of a chip’s features requires the use of higher purity materials. Therefore, all liquid chemicals and solid materials used in semiconductor processes should contain extremely low levels of contaminants.

Ultrapure water(UPW) is one of the most important chemicals in the production of semiconductor devices and is used extensively for all wet-processing steps, including wafer-rinsing and the dilution of compounds used in chemical baths.

During these critical steps, contaminants from the chemical baths and from the rinsing water can be adsorbed and precipitated onto the silicon surface via a chain of chemical and electrochemical reactions.

The metallic contaminants at concentration levels of 50 ppq present in the critical areas of the finished product can change the electrical parameters of the components of an integrated circuit and cause it to fail final electrical tests. Since UPW is essential to the producers of semiconductor materials, the measurement of its purity is of the highest importance.

A number of organizations and groups developed and published standards associated with the production and the point of delivery(POD) of UPW.

For semiconductors and microelectronics, they include Semiconductor Equipment and Materials International(SEMI) and American Society for Testing and Materials International(ASTM International).1

In the latest SEMI F63-0918 "Guide for Ultrapure Water used in semiconductor processing”,2

Among other requirements, the target values for 26 metallic contaminants are less than 1 ppt with the exception of B (50ppt) and Ni (3 ppt).

Reported method detection limits(MDLs), provided as a reference, shows values of 0.5 ppt for all elements with the exception of B(15ppt) and Ni (1.6ppt).

The only technology that can determine this suite of elements at such low levels in a short period of time is inductively coupled plasma mass spectrometry(ICP-MS).

In this application note, results of the UPW analysis obtained using an ICP-MS instrument from PerkinElmer, the NexION® 5000 as described below, will be shown.

Experimental

Instrumentation

PerkinElmer’s NexION 5000 ICP-MS is a Multi-quadrupole system with triple quadrupole technology described in detail in the NexION 5000 product note.3

The NexION 5000 represents a truly significant advancement in ICP mass spectrometry and in the removal of spectral interferences. The novel Triple Cone Interface(TCI) with OmniRing™ technology,4

The patented plasma generator and LumiCoil™ RF coil are designed to enhance analytical performance, sensitivity of the instrument, as well as reliability.

The balanced and free-running RF generator design delivers improved robustness, high efficiency, wide power range and ensures fast power-switching between Cold and Hot Plasma modes.

Multi-mode methods can now take advantage of these technologies in combination with a cell-based Reaction mode(in the Universal Cell) and triple quadrupole technology, yielding superior polyatomic interference removal that can further improve detection limits(DLs) and background equivalent concentrations(BECs).

Unlike passive cells, such as octopoles and hexapoles, the Universal Cell is a quadrupole; therefore, it has the ability to control the reaction chemistry through the implementation of the rejection parameter “q”. This parameter is able to prevent byproducts of the original reaction from forming new interferences with any water vapor residues or cell gas impurities which may have been introduced into the cell.

In addition, controlling the chemistry allows the use of highly reactive, non-diluted gases in the cell, which greatly enhances the elimination of interferences and ensures predictable reactions.

With four gas channels available, up to four gases can be used in the same method delivering ultimate flexibility in the removal of any particular interference.

Instrumental Conditions

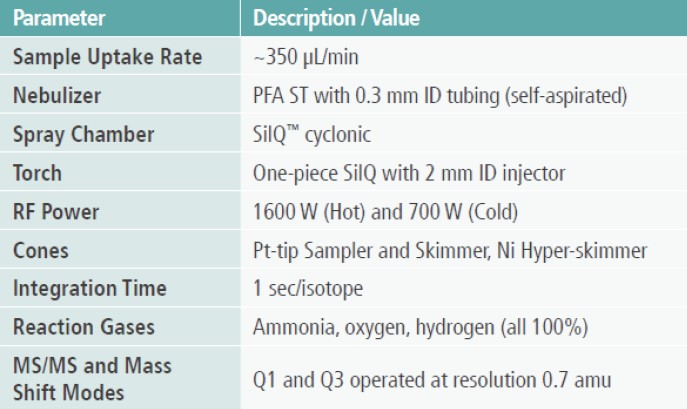

All analyses were performed on the NexION 5000 ICP-MS in a standard configuration with the instrumental parameters shown in Table 1.

Table 1. Instrumental Parameters

Background equivalent concentrations and detection limits for all elements were run in Hot Plasma mode using 1600 W RF power.

For a few elements that work well in Cold Plasma mode(700 W), BECs and DLs are also shown.

A Focusing mode with MS/MS or Mass Shift was used for all analysis.

A Reaction mode with NH3, or O2, or H2, or a mixture of gases is the most effective way of removing spectral interferences by changing them into atoms or ions of a different mass, or by creating a cluster ion with an analyte (Mass Shift). In MS/MS mode, Q1 and Q3 are set up at the same mass, while in Mass Shift mode, an analyte is measured at a higher mass as an ion product with a reaction gas.

Results and Discussion

Interference removal by chemical reactions and Mass Shift mode have been used for many years since the introduction of the Dynamic Reaction Cell(DRC) in 1999. Triple quadrupole technology makes these modes even more effective since the first transmission quadrupole(Q1) set at <0.7 amu resolution does not allow other species than those at the analyte mass to be transmitted further. This operation effectively cleans the ion beam and the background before it enters the cell. The Universal Cell, via gas reactions, deals with spectral interferences and then the analyzing quadrupole(Q3), also set at <0.7 amu resolution, rejects products other than an analyte of interest.

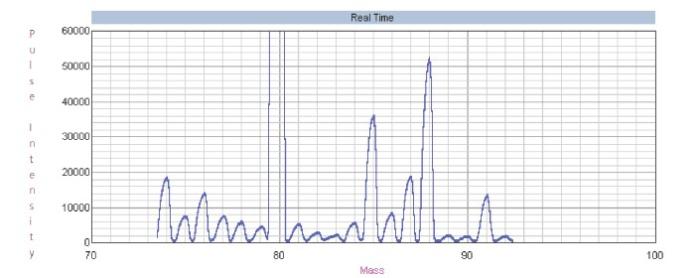

Scans shown in Figures 1 and 2 explain in detail how Reaction mode with triple quadrupole technology works.

In Figure 1, there is a Q3 scan(Single Quad mode) of a 100 ppt multielement standard from mass 75 to 92 while O2 was introduced into the Universal Cell.

The Q1 quadrupole acts as an ion guide transmitting all masses. The analyzed standard is a mixture of 50 elements including Ge, Zr and diluted HCl. Multiple peaks from the components of this standard are displayed and a peak formed by AsO is present at mass 91.

Figure 1. Q3 scan(Single Quad) of a 100-ppt mixed-element standard from mass 75 to 92.(Left)

Figure 2. MS/MS scan of a 100-ppt mixed-element standard from mass 75 to 92 while Q1 transmits only ions at mass 75.(Right)

The same mixed-element standard solution was scanned in Product Ion Scan mode with O₂(Figure 2), with Q1 set to 0.7 amu resolution at mass 75 instead of transmitting all ions. The plot shows a clean background with only two peaks - CoO and ArCl at mass 75 and As seen as AsO at mass 91. Consequently, arsenic is measured in the Mass Shift mode after reaction with O₂ without having to worry about potential interferences from Ge, Zr and Cl.

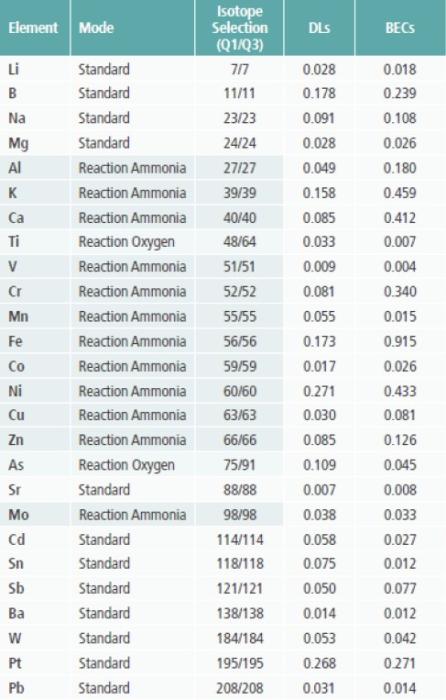

Using MS/MS and Mass Shift modes with reaction gases(Reaction mode) and without reaction gases(Standard mode), DLs and BECs were measured for 50 elements in UPW. Hot plasma conditions and onesecond integration time per isotope was used for this analysis. Table 2 shows the results of 26 semiconductor-essential elements.

Table 2. UPW DLs and BECs in ppt for 26 essential elements for the semiconductor industry measured in Hot Plasma mode.

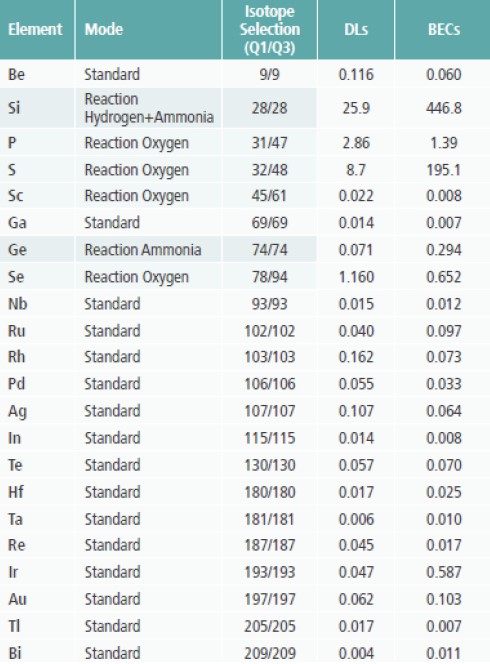

Table 3. UPW DLs and BECs in ppt for non-essential elements for the semiconductor industry measured in Hot Plasma mode.

Detection limits in Hot Plasma mode for all 26 essential elements for the semiconductor industry were found to have concentrations lower than 0.3 ppt, easily fulfilling the 1-ppt requirement by SEMI or ASTM standards. BECs for most of the elements were found to be less than 0.5 ppt, demonstrating the effectiveness of the gas reactions and the MS/MS modes in removing spectral interferences.

In Table 3, DLs and BECs for an additional 24 elements are shown with similarly low values for both parameters.

For the BEC and DL measurements, calibration curves were established with 10, 20, 40 and 60 ppt standards. All curves had linear regressions values(r2)> 0.999, demonstrating the linearity of the analysis, the ability to accurately measure at low concentrations, and the effectiveness of the interference removal. Figure 3 shows four typical calibration curves in Standard MS/MS mode, in Reaction (NH3) MS/MS mode and in Reaction (O₂) Mass Shift mode respectively.

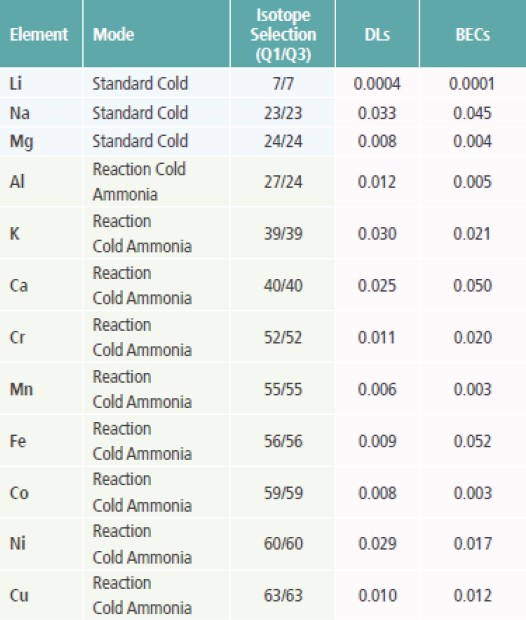

Cold Plasma mode, in conjunction with MS/MS, is able to obtain extremely low DLs and BECs in Standard and Reaction (NH3) modes for a few elements that have Ar-based interferences or whose sensitivity is enhanced by the reduction of Ar ions in the plasma stream (Table 4).

Table 4. UPW DLs and BECs in ppt measured in Cold Plasma mode.

Conclusion

The presented data has clearly demonstrated that the NexION 5000 multi-quadrupole ICP-MS, with the patented SMARTintro™ sample introduction system, LumiCoil™ load coil, 34-MHz RF plasma generator, Universal Cell with four gases and triple quadrupole technology, is designed to provide outstanding analytical performance in terms of DLs and BECs, as is needed for the semiconductor industry today and for the foreseeable future.

PerkinElmer의 'Characterization of Ultrapure Water Using NexION 5000 ICP-MS'에 대한 궁금한 내용은 본 원고자료를 제공한 한국퍼킨엘머를 통하여 확인할 수 있다.

Reference(참고문헌):

1. ASTM D5127-13 “Standard Guide for Ultra-Pure Water Used in the Electronics and Semiconductor Industries”.

2. SEMI F63-0918 "Guide for ultrapure water used in semiconductor processing".

3. “NexION 5000 Multi-Quadrupole ICP-MS” PerkinElmer Product Note, 2020.

4. Badiei H., “Advantages of a Novel Interface Design for NexION 5000 ICP-MS” PerkinElmer Technical Note, 2020.

<이 기사는 사이언스21 매거진 2020년 5월호에 게재 되었습니다.>